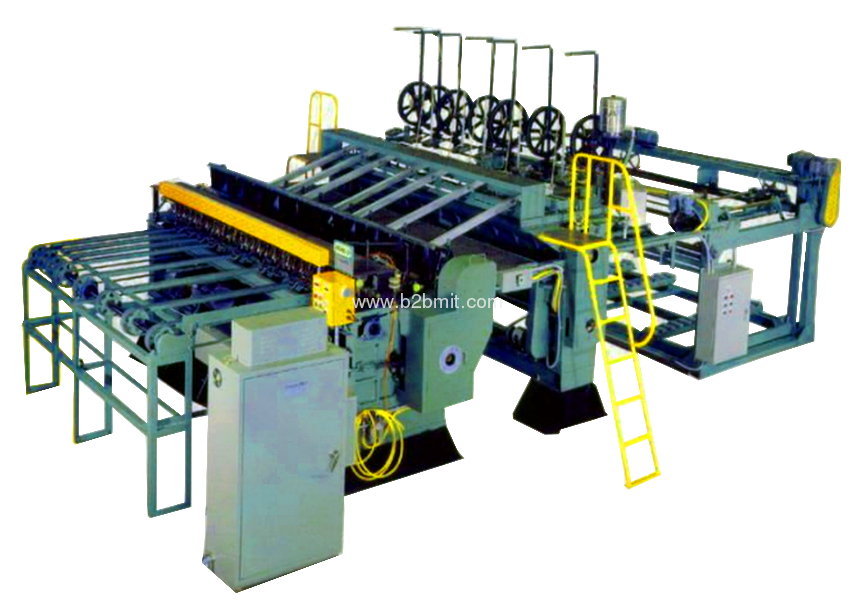

1. Save material:Using PLC type electronic

detector reduced odd back veneer to minimum wasting 5mm.

2. Save labor :Operation is very simple, one or two workers are available.

3. High quality:Through electronic detector, jointing by glue paper, we can

produce very average thickness back veneer and available thickness 0.5mm

-1.2mm.

4. You can easily adjust the 6'~8' size to match your requirement for use.

5. The stacker is the latest conveyer stacker which make the stack orderly and

keep well-arranged.

6. Raising product quantity:With 3pcs sliced veneer jointing to one sheet

.One hour can produce over 190 pcs perfect back veneer.

SPECIFICATION: Back Veneer

Composer

|

Model

|

CI-BVC8-IVS

|

|

Working

veneer width

|

1,800-2,600mm

|

|

Working

veneer thickness

|

0.6-1.2mm

|

|

Min.

Working veneer width

|

50mm

|

|

Thickness

detecting point

|

26points

|

|

Working

Thickness

|

0.6mm

to 1.4mm

|

|

Taping

position

|

7position

|

|

Veneer

feeding speed

|

20m/min

|

|

Automatic

cutting Length

|

900-1,300mm

|

|

Motor

for

|

for

feed

|

1.5kw

|

|

for

cam drive

|

2.2kw

|

|

for

conveyor before clipper

|

0.4kw

|

|

for

conveyor after clipper

|

0.4kw

|

|

for

delivery conveyor

|

0.4kw

|

|

for

veneer dropping

|

0.4kw

|

|

for

table lifting

|

1.5kw

|

|

for

full size clipper (Induction AC Servo)

|

2.2kw

|

|

Area

Occupied

|

5.0Mw

X 9.6ML

|

|

Machine

weigh

|

N.M.9,325kg

|

|

Measurement

|

50M3

|

Taiwan

Taiwan